Modular Seating Success - Changing the brief for positive results

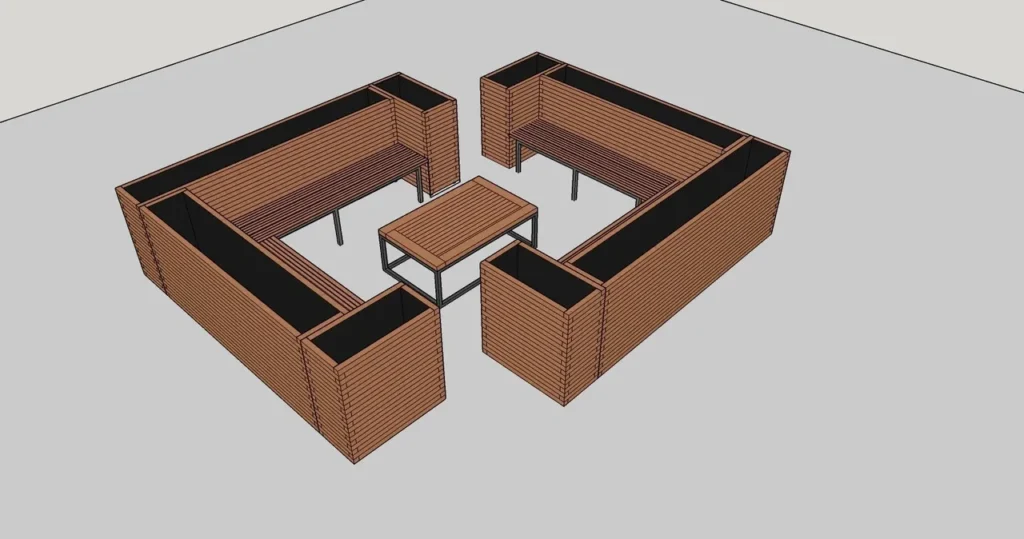

We’re pleased to report on the recent success of modularising our Somerset Wooden Garden Planters into a significant backed seating arrangement, with associated Outdoor Coffee Tables.

Having been approached by a London based design and construction company late in November 2022 with designs for an outdoor seating area for a flagship industrial unit, Bespoke Outdoor was presented with a significant number of challenges to install a number of large seated areas with limited access and on a very tight budget. We were presented with draft designs and asked for a proposal.

Immediately we set to work understanding the plans and how we could successfully interpret them using our tried and tested, high quality existing product. Our first hurdle was seeking permission to alter the design to better suit the end users; we noticed the seating depth would lead to an uncomfortable seated position. The design also specified a wooden clad area to the front face of the seating, meaning there was no option for legs and feet to rest underneath the bench as you naturally do when sitting forwards.

Upon presenting to our client, they took our feedback on board and welcomed the design alteration suggestions, which in turn were approved by the end client with notable gratitude. Having prevented a significant ergonomic disaster, the client’s confidence in Bespoke Outdoor was transparently growing.

Having gained the trust of our client, we set about how best to ‘break up’ the proposed layout to be economical and practical, whilst remaining eye-catching and of a high quality. We put together a 6 part planter module recommendation consisting of 4 Somerset wooden planters and 2 steel framed, powder coated, bench sections. All of which could be connected with less than 20 screws and 15 minutes of time by the client.

The nervous wait then came having submitted our proposal, with many months passing without any confirmation of success. Fortunately by late Spring, the green light was given to our proposal, where we learnt of our significant cost saving versus all other companies who were invited to tender. Our foresight to modularise the design had removed requirements others had failed to, such as the need to crane the items into place, and reducing the work space needed during production for each bench. It also allowed the entire order to fit on a dedicated 18T lorry, as opposed to multiple trips and difficult, awkward loading procedures.

Having secured an entire month’s labour for our production team, and having positive feedback from both our client and the end user once the final products were put into place, we look back with extreme positivity on a job well done at all stages, and relish the thought of similar work being placed with us in due course.